1、Stainless steel pipe and pipe fitting source factory has the following characteristics The plant is large With an area of nearly 79,000 m², WEGS has formed a group-controlled company with Shanghai as the headquarters and Xianning, Hubei province as the production base.

WEGS has ranked first in market share in Shanghai for three consecutive years and owns the largest specialized production base of stainless steel pipes and fittings in China.

Meeting diverse needs: The source factory has a professional technical team and production equipment, which can customize products according to customers' different specifications, shapes, materials and other requirements. For example, it can customize stainless steel pipes with specific curvature and wall thickness for special architectural projects to meet the unique appearance and structural requirements of architectural design.

Flexible production: The response speed to customized orders is fast, and the production arrangement can be flexibly adjusted according to customer needs, so that samples and batch production can be completed in a short time to adapt to the changing market demand.

Comprehensive Quality Management System: Our system features a full-process quality control framework spanning from raw material inspection to finished product release. Each batch undergoes rigorous testing to ensure material compliance with standards. During production, multiple quality control checkpoints are implemented, with real-time monitoring of critical parameters including dimensional accuracy of steel pipes, surface quality, and compressive strength of pipe fittings.

Professional testing equipment: With a CNAS laboratory, equipped with professional testing equipment, such as spectral analyzer to detect material composition, ultrasonic flaw detector to detect internal defects, etc., to ensure stable and reliable product quality, in line with relevant national standards and industry requirements.

Keep up with the industry trend: in order to maintain market competitiveness, we continue to invest in R&D resources, pay attention to the development trend of new technologies and new processes in the industry, and actively introduce and apply them. For example, research and development of new stainless steel pipe welding process to improve welding quality and production efficiency.

5、Product innovation: independently develop new products according to market demand and industry development trend. For example, develop stainless steel pipes and pipe fittings with higher corrosion resistance to meet the needs of chemical industry, ocean and other special fields.

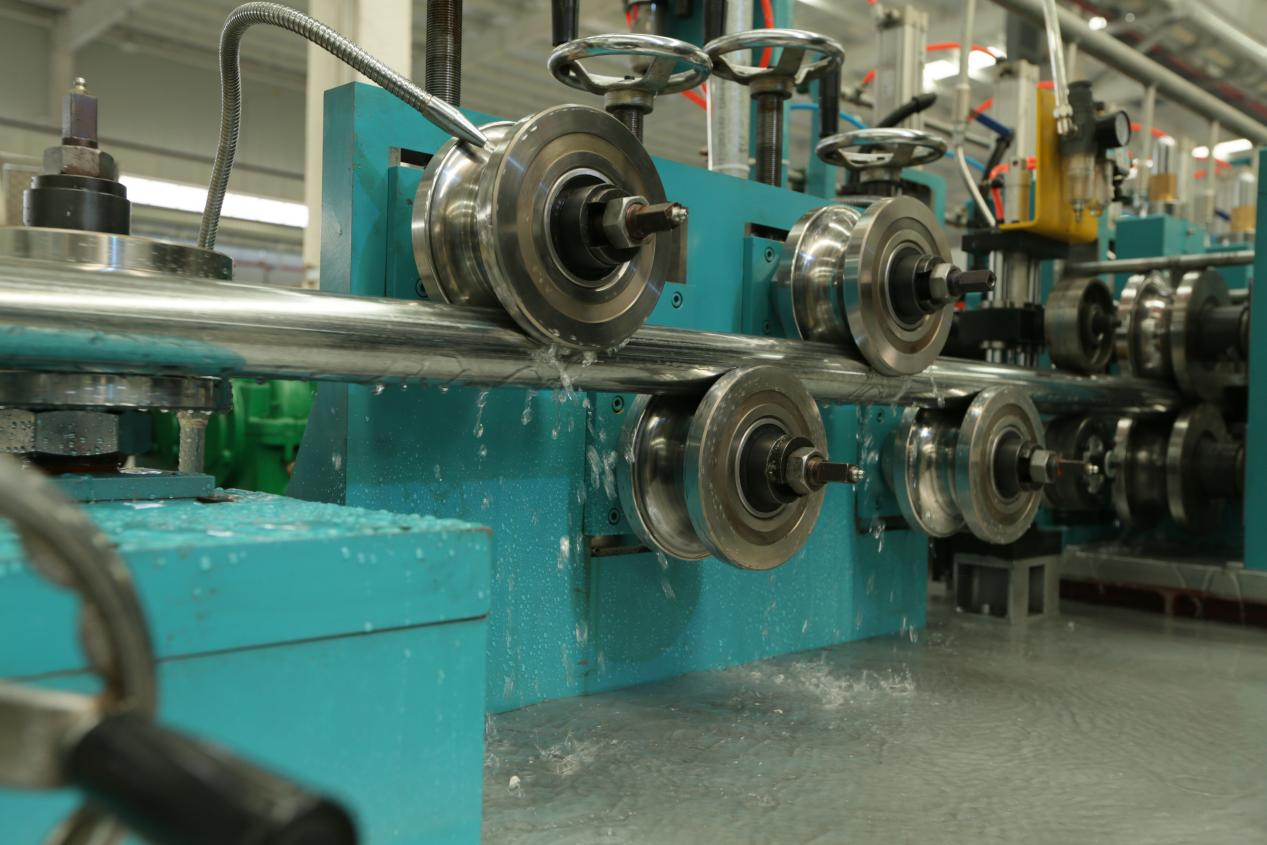

Advanced and complete equipment: a series of advanced and complete production equipment, such as large tube making machine, pipe forming machine, heat treatment equipment, etc., can achieve large-scale and high efficiency production, to meet the batch needs of different customers, whether small batch sample production or large-scale order delivery can be handled easily.

Large production capacity: With a large production capacity, it can complete the production tasks of a large number of orders in a short time on the premise of ensuring product quality, and ensure the timeliness of market supply, especially in the peak season of market demand.

Technical Support Specialization: With our professional technical team, we provide clients with expert technical consultation and customized solutions. For instance, during equipment selection, we recommend suitable stainless steel pipes and fittings based on application scenarios and technical requirements. When installation challenges arise, we offer both on-site guidance and remote technical support to ensure smooth implementation.

Quick response to after-sales problems: respond quickly to after-sales problems, and can timely deal with the product quality problems or questions in use reported by customers. Through reissue, replacement, maintenance and other methods, customers can ensure normal use and improve customer satisfaction.